Services

France Evaporation provides complete, flexible and responsive engineering solutions. Our teams act once the project has been defined monitoring each facility until it is commissioned.

France Evaporation ensures highly reactive long term monitoring to ensure the longevity and performance of each facility.

Our teams have a laboratory fully dedicated to process validation and developing pilot units which enable the safe movement from engineering to industrial production and guarantee the performance of each facility.

France Evaporation provides complete, flexible and responsive engineering solutions. Our teams act once the project has been defined monitoring each facility until it is commissioned.

France Evaporation ensures highly reactive long term monitoring to ensure the longevity and performance of each facility.

Our teams have a laboratory fully dedicated to process validation and developing pilot units which enable the safe movement from engineering to industrial production and guarantee the performance of each facility.

n a context of increasing energy costs, France Evaporation developed a thorough expertise in energy-saving systems designed to optimize industrial evaporation and cristallization processes.

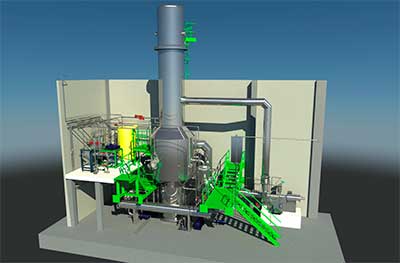

Leading provider of evaporation and concentration technologies, France Evaporation has developed a proprietary high-performance offering rental of mobile units for the treatment of leachate, digestate and liquid industrial effluents.

Mobile units offer large capacity, flexible, economical and rapid evaporation solutions to be implemented.

Road transport of the units takes place using adapted trailers, to reach most industrial sites. No special permissions are required and any type of road can be used.

With a capacity of 4 tonnes per hour for falling film and forced circulation evaporation, direct vapour or mechanical compression can be used.

An absolutely confident operation

France Evaporation's additional services ensure that installation and operation is managed with confidence, with minimal intervention from your teams:

- Standalone facility, delivered turnkey

- Fully controlled and automated units

- Remote monitoring (3G connection included)

- Operating assistance

- Management of consumables and reagents

- Availability rate over 90%

All the advantages of renting

- No investment

- Rapid implementation

- Minimal maintenance

- Rental periods adapted to any type of problem

Low operating costs

Specialists in thermal recovery, France Evaporation designs high-performance solutions in terms of energy efficiency and operating costs.

- Power consumption less than 100 kW

- Thermal consumption of less than 100 kg/hr

- 26 kW.h/hr power per ton of evaporated water

Safety, quality and environmental respect

100% secure, our mobile units provide a discharge quality in the natural environment which permits its usage on any land type and on every environment.

Technical specifications

- Skid unit

- Falling film evaporator

- Forced circulation evaporator

- Mechanical Vapour Compression

- Optional boiler

- Footprint: 6m x 6m

- Height: 7.5m

France Evaporation is known for the quality of its follow-up for the facilities it develops.

Training

Our engineers train your teams in the installed units. This specific training is provided in the field by the designers of the system. Our goal: to make you autonomous in the control of the unit as soon as possible. Our teams remain responsible until the facility is 100% usable by operators.

Assistance

Our engineers ensure the monitoring of the units installed. Some of France Evaporation's facilities have been operational for over 20 years.

This field or remote assistance guarantees the maximum availability and profitability of the facility.

Maintenance

Made to last, our facilities are subject to developmental, predictive and complete curative maintenance programmes to ensure maximum service life and stable performances.

France Evaporation takes full responsibility for the facility's assembly and commissioning.

A dedicated installation team

For each installation, France Evaporation commissions a dedicated team, led by an experienced engineer. This team coordinates all operations, from the factory to the attainment of the specified performances.

Commissioned by the project team

Testing and start-up is performed by the teams that sized the facilities, which guarantees our engineers efficient and rapid feedback. This enables the continuous improvement of our expertise and performance of our facilities.

Since its creation, France Evaporation has provided nearly a hundred units of all sizes, in very different contexts.

France Evaporation has built a network of partners and subcontractors to ensure the quality of its work, supervised by a proven quality policy.

A comprehensive network of long-term partners

Boiler making, electricity, electronics, Chemicals, transport, installation: France Evaporation is surrounded by a network of reliable and skilled partners during all stages of the manufacturing and industrial assembly.

We are able to comply with your material specifications (instrumentation, valves, pumps etc).

Proven quality policy

The manufacturing, transport, installation and assembly of the structures are organised, managed and controlled by our teams as part of a quality policy built on the experience and the desire to achieve the best technical performances.

These operations are subject to extensive documentation and full traceability.

Permanent technology monitoring

Our teams permanently monitor technology to identify, assess and integrate the best performing and most efficient solutions into the processes developed.

France Evaporation is one of the few actors in the market to develop pilot units in order to validate 100% of every evaporation, crystallisation or stripping process.

Evaporation France has a laboratory and a pilot hall. Test results guarantee the performance of the developed processes, including unprecedented concentration problems or technological innovations.

We also have the opportunity to develop pilots for specific applications.

Pilot units specifically allow the following operations:

- produce a representative amount of the concentrated product to validate the system

- produce a sufficient amount of condensates and check their quality

- validate thermo-chemical data on the product

- test and measure the operation of a pilot on the product after several hours, days or even weeks, including on-site

Pilot units available:

- 4 evaporation pilots, 30 kg/hr - 300 kg/hr of evaporation (2 mobiles units)

- 2 stripping pilots (30 kg/hr and 300 kg/hr of treatment), 1 mobile

- 1 IFC® crystallisation pilot

Associated facilities:

- launch tanks (heated or not)

- centrifuge for crystals

- drying of crystals

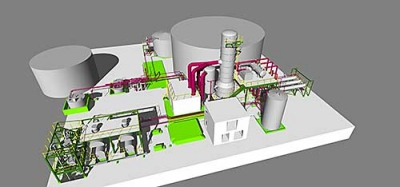

Specialised and experienced, our teams develop evaporation and crystallisation industrial facilities, mobilising equipment, technologies and the most advanced know-how in the sector.

Custom process

Our engineers determine the best process for your product, your budget and most importantly, your objectives: simplicity, reliability, working costs, product quality, energy efficiency, sanitation, etc.

Innovation and technologies

Our facilities incorporate the most advanced technologies and the results of R&D work carried out continuously in our laboratory. Our engineers are in constant contact with industrial technology leaders to quickly integrate innovations in our processes.

The recommended technologies are evaluated based on your goals and your production or facility constraints.

Our expertise is inspired by dozens of facilities internationally executed in all industrial sectors.

Pragmatism and experience

Our industrial designs are based on unique experience, which puts our teams at the centre of technical challenges and our clients' objectives every day. Pragmatic and proven, our solutions guarantee operational and reliable facilities.

Exclusive expertise

France Evaporation has developed several exclusive patented technologies from our research and development work and our partnerships with top scientific specialists.

These skills have helped us to gain the trust of the most demanding industries and often achieve unmatched performances in certain industrial processes.

Development and optimisation

Our teams are also comfortable with the development of new processes and the optimisation of existing facilities. Our interventions are especially effective in optimising the process and energy efficiency of facilities.

Complete engineering

France Evaporation develops complete evaporation processes which integrate all necessary technologies.

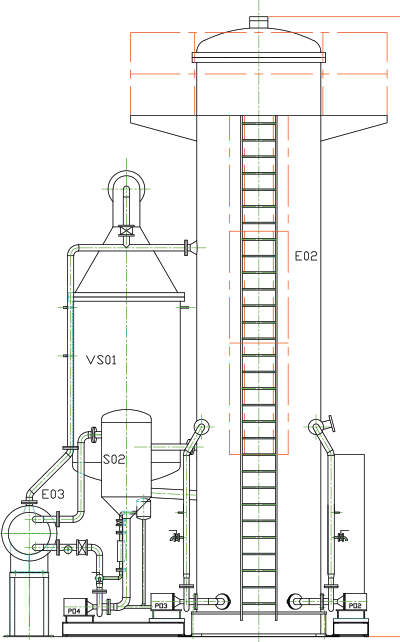

The engineering works include:

- the drafting and development of Process Flow Diagrams (PFD) and Process and Instrumentation Diagrams (PID)

- autocad and CADWorks 3D modelling

- piping isometrics

- designing and production according to CODAP, ASME computer calculation codes, etc.

- the completion of detailed drawings

- testing and verification of sheet metal equipment (control of welds, remote blasting on the welds, DESP, etc.)

- control and automation (any system)