Chemical

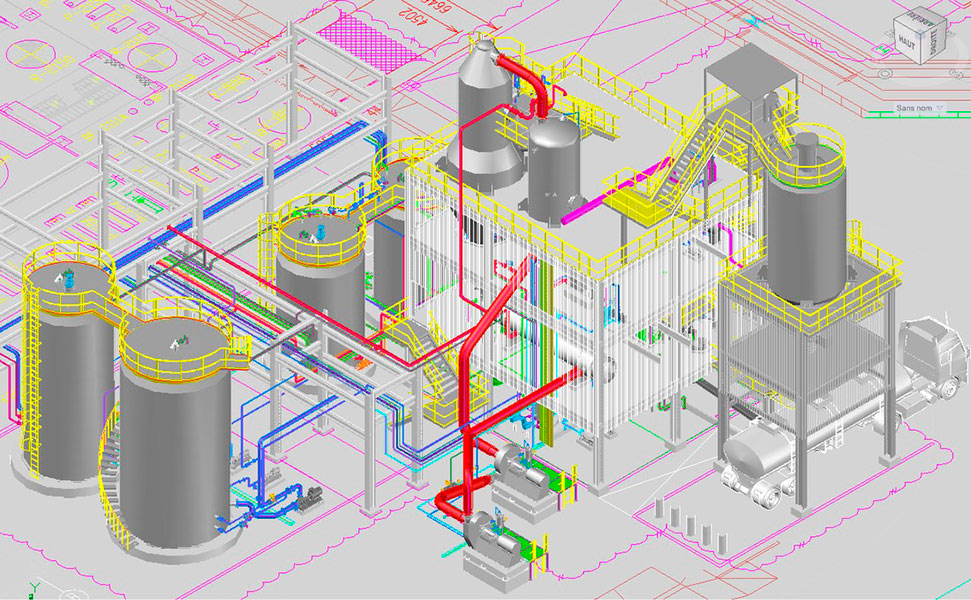

France Evaporation has been developing evaporation, concentration and crystallisation solutions for the chemical industry for over 20 years. Our facilities meet the simplest optimization requests up to the designing of complete production processes of high added value compounds.

Home > Industries > Chemical

Applications

- production of salt: Na2SO4, (NH4) 2SO4, K2SO4, etc.

- soda, carbonate and sodium bicarbonate concentrate

- sulphuric acid, ammonium sulphate, ferric chloride concentrate, etc.

- concentration of washing water of manufacturing tanks

- recovery of solvents (alcohol, acetone, toluene, hexane, etc.)

Our strengths

The multidisciplinary expertise and experience of our teams are major assets for rapidly develop the most suitable methods for your quality constraints, budget and industrial requirements.

The processes developed by France Evaporation combine evaporation, crystallisation and stripping to get maximum value from the products and by-products of the process.

Specialists in thermal energy, our teams have very advanced expertise in the optimisation of existing energy facilities including very large crystallization and evaporation systems.

Innovation 2015

Crystal clear solutions

IFC®: The new generation of high performance crystallizers

Discover the exclusive IFC® technology

Larger size, narrower distribution

- Chemical

- Salts and Mines

- Fertilizers

- Food Industry

- Water and Waste Management

- Pharmaceutical and Cosmetics