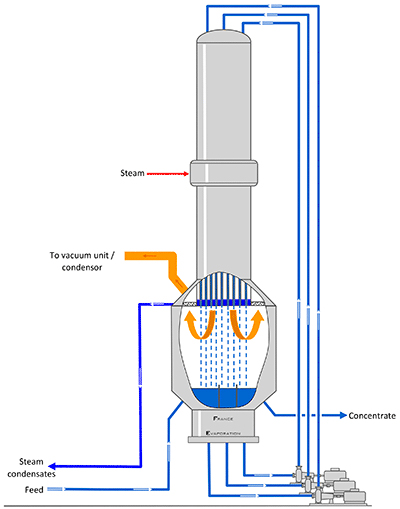

Falling Film Evaporation

The falling film evaporation technology has several economic and industrial benefits. The capacity of these units can range from 10 k/hr to more than 100 t/hr.

Home > Technologies > Evaporation > Falling film evaporation

Smaller footprint

Falling film evaporators are installed vertically installed and have a small footprint. In addition, the separator can be easily integrated into the evaporator to further reduce the floor area used.

Low residence time

The product flows by gravity in the exchange tubes by creating a thin liquid film on the inner walls. By varying the liquid’s speed, it is possible to control the thickness of this liquid film and thus reduce the product’s residence time.

Reduced operating cost

Pumping costs per tonne treated with a falling film evaporator are much lower than those for a forced circulation evaporator.

Reduced investment

The construction cost of a falling film evaporator is lower, notably due to a compact design (separator and scrubber in a single block) and the absence of structural costs.

Low foaming

The falling film evaporator is great for products sensitive to foaming.

Greater sensitivity to clogging

The falling film technology is more sensitive to clogging, especially compared to forced circulation evaporation.

It is not recommended on the clogging products, close to crystallization or viscous.