Evaporation

The evaporation process solves a near-infinite number of industrial problems related to the concentration, volume reduction and treatment of effluents.

Home > Technologies > Evaporation

Our teams have been working for over 20 years to develop these solutions in many industrial sectors including chemical, pharmaceutical, mining, food processing, oil and fuel, waste treatment, water treatment, textiles, etc. Being experienced specialists of the evaporation process, our teams master all available technologies and have a return of almost unique experience in the sector and valuable expertise to define the most relevant system as concerns your goals and budget. The units are custom-built to meet a wide range of requirements.

A capacity tailored to your needs

The unit’s capacity is defined according to your needs: from 10 kg/hr to more than 100 t/hr.

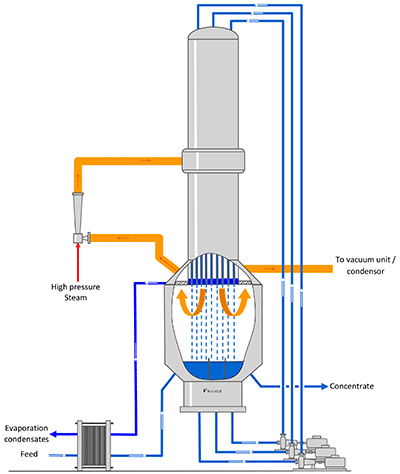

Working pressure: empty or pressurised

he working pressure can range from a few millibars to several bars.

The working pressure can range from a few millibars to several bars.

- Nature of the product

– Products which are insensitive to temperature are preferably concentrated at atmospheric pressure to reduce investment cost.

– The most sensitive products are concentrated at a lower pressure (thus at low temperature). - Process

- Energy recovery

Materials adapted to products

The materials of construction used are selected on a product-by-product basis.

The most commonly used material is 316L stainless steel or duplex stainless steel, but for products at risk of corrosion, higher grades can be used (super duplex, titanium, Alloy 31, graphite, plastic materials, etc.).

France Evaporation can also work with less expensive materials such as steel, when the product permits.

Selecting the most suitable evaporation technology

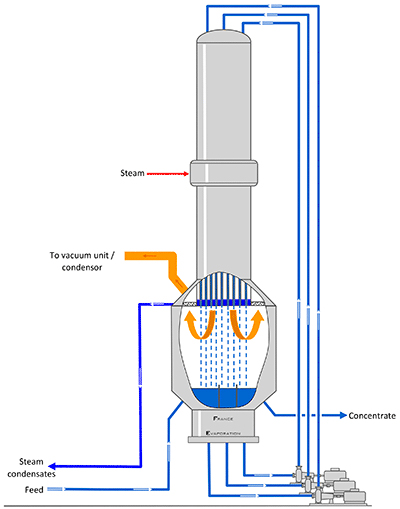

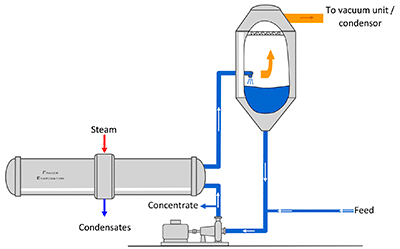

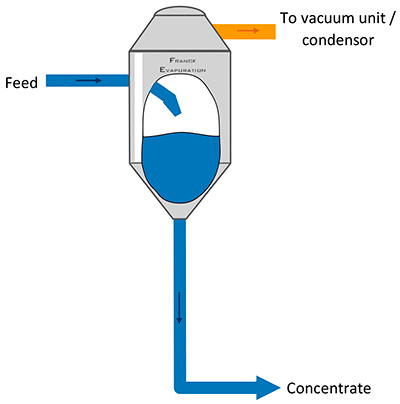

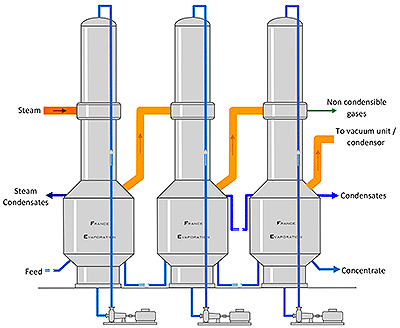

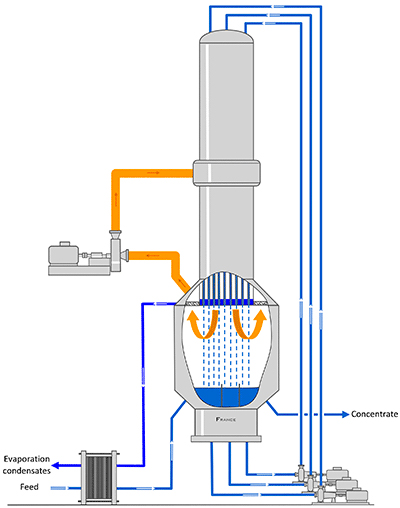

Falling film, forced circulation, flash cooling, etc.: France Evaporation determines the technology or combination of technologies most suited to the concentration of your product regarding your teams.

Energy optimisations

Depending on the capacity, location and cost of available energy, France Evaporation assists you in selecting the best thermal processes. Objective: to reduce the overall energy bill.

Where the use of steam generates significant costs, we prefer processes that use Mechanical Vapour Compression or Recompression (MVC-MVR) in order to significantly reduce the overall energy costs of the facility.

Installations adapted to existing constraints

In the case of a facility in an existing building, France Evaporation optimises the integration of the unit into the building down to the smallest detail, while respecting the performance of the process.

Installation, testing and start-up assembled by us

France Evaporation tests and starts up product installations with the help of your teams, in order to validate operation under industrial conditions over several weeks.

Our teams train your staff directly in the use of the installation.