Forced Circulation Evaporation

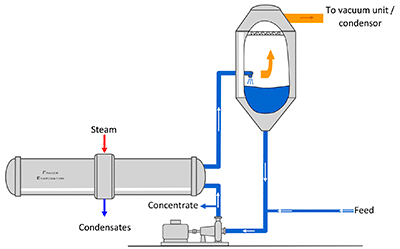

The forced-circulation evaporator consists of a heat exchanger, a separator and a circulation pump.

Home > Technologies > Evaporation > Forced circulation evaporation

The product is sent to the heat exchanger, where it is heated and then sent to the separator. After evaporation, the liquid part is pumped back to the heat exchanger.

Forced circulation evaporators are ideal for concentrating viscous fluids containing a high proportion of suspended solids.

Low sensitivity to soiling

The circulation pump ensures high speed in the exchange tubes, reducing the amount of deposits on the walls and avoiding evaporation and therefore the risk of over-concentration.

Accepts suspended solids

For products close to crystallization: unlike the falling-flow evaporator, the forced-circulation evaporator can accept suspended particles or the presence of crystals, without clogging the exchange tubes.

Financial impact

The initial investment and footprint for these systems is higher than for falling-flow evaporators, which are therefore often preferred.