Industrial design

Specialised and experienced, our teams develop evaporation and crystallisation industrial facilities, mobilising equipment, technologies and the most advanced know-how in the sector.

Custom process

Our engineers determine the best process for your product, your budget and most importantly, your objectives: simplicity, reliability, working costs, product quality, energy efficiency, sanitation, etc.

Innovation and technologies

Our facilities incorporate the most advanced technologies and the results of R&D work carried out continuously in our laboratory. Our engineers are in constant contact with industrial technology leaders to quickly integrate innovations in our processes.

The recommended technologies are evaluated based on your goals and your production or facility constraints.

Our expertise is inspired by dozens of facilities internationally executed in all industrial sectors.

Pragmatism and experience

Our industrial designs are based on unique experience, which puts our teams at the centre of technical challenges and our clients’ objectives every day. Pragmatic and proven, our solutions guarantee operational and reliable facilities.

Exclusive expertise

France Evaporation has developed several exclusive patented technologies from our research and development work and our partnerships with top scientific specialists.

These skills have helped us to gain the trust of the most demanding industries and often achieve unmatched performances in certain industrial processes.

Development and optimisation

Our teams are also comfortable with the development of new processes and the optimisation of existing facilities. Our interventions are especially effective in optimising the process and energy efficiency of facilities.

Complete engineering

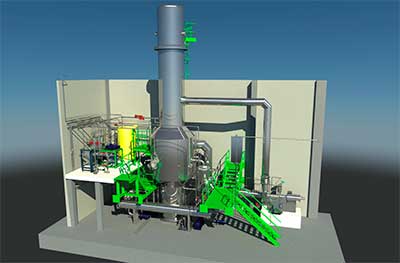

France Evaporation develops complete evaporation processes which integrate all necessary technologies.

The engineering works include:

- the drafting and development of Process Flow Diagrams (PFD) and Process and Instrumentation Diagrams (PID)

- autocad and CADWorks 3D modelling

- piping isometrics

- designing and production according to CODAP, ASME computer calculation codes, etc.

- the completion of detailed drawings

- testing and verification of sheet metal equipment (control of welds, remote blasting on the welds, DESP, etc.)

- control and automation (any system)