Multiple Effect Evaporation

The multiple effect evaporation processes can optimise the energy efficiency of facilities through the recycling of vapour.

Home > Technologies > Evaporation > Multiple Effect Evaporation

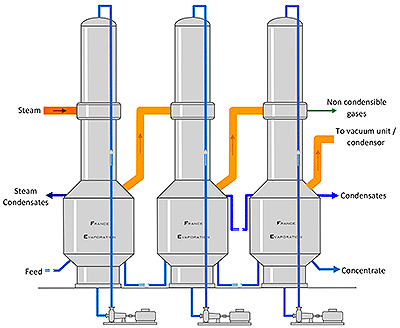

Functioning

The vapour supplied during the first effect produces the vapour at a lower pressure. These vapours are then used in a second effect as a vapour heating steam.

The number of effects vary and can go right up to 8. The number of effects is chosen according to the investment and operating cost.

The vapours at the outlet of the last effect should be condensed.

Suitable for any type of evaporator

The multiple effect evaporator can be made up of falling film, forced or flash-cooling circulation evaporators.

Multi-effect evaporator applications

This technology is great when the cost of vapour is low.