Industries

Technologies and systems developed by France Evaporation provide efficient, economic and ecological solutions to many current industrial issues.

Our engineers have developed very specialized sector expertise and our facilities now offer a true concentrate of know-how, fuelled by over 20 years of experience.

Technologies and systems developed by France Evaporation provide efficient, economic and ecological solutions to many current industrial issues.

Our engineers have developed very specialized sector expertise and our facilities now offer a true concentrate of know-how, fuelled by over 20 years of experience.

Our concentration and crystallisation evaporation solutions cover a wide range of fertiliser production needs: nitrate fertiliser, ammonium, potassium and phosphate.

France Evaporation's facilities ensure quality production: crystal size and purity of components.

Some examples of fertilizer:

- potassium sulphate K2SO4 -

learn more

learn more - ammonium sulphate (NH4)2SO4 -

learn more

learn more - ammonium phosphate

- potassium phosphate

- etc.

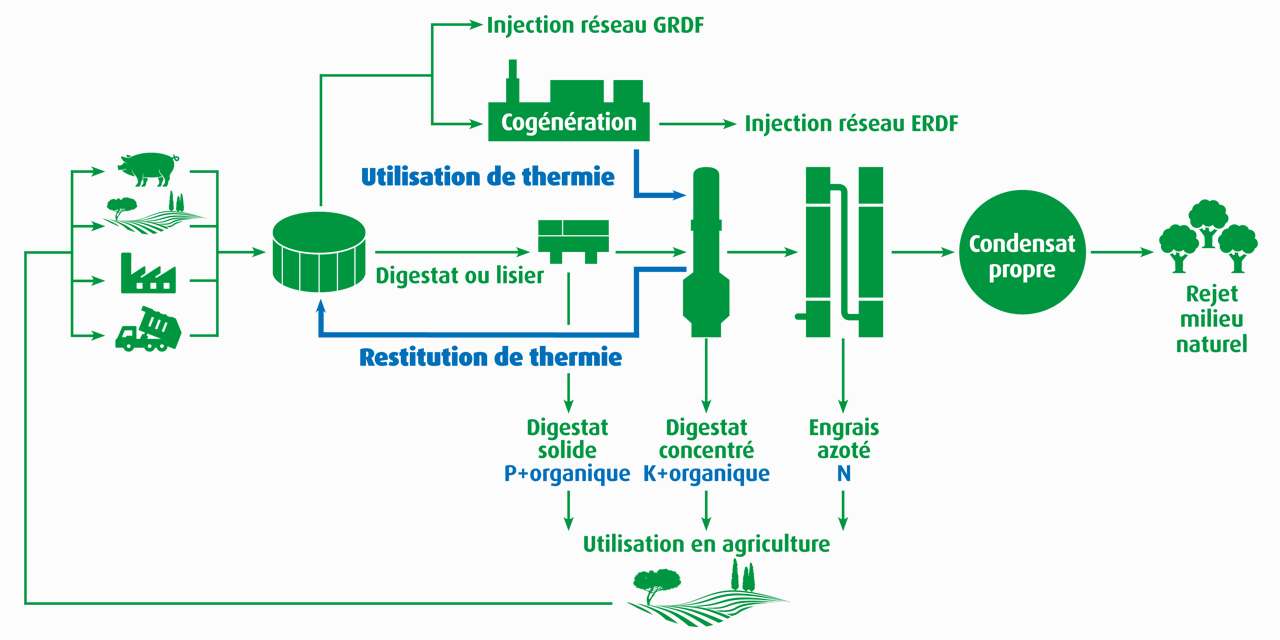

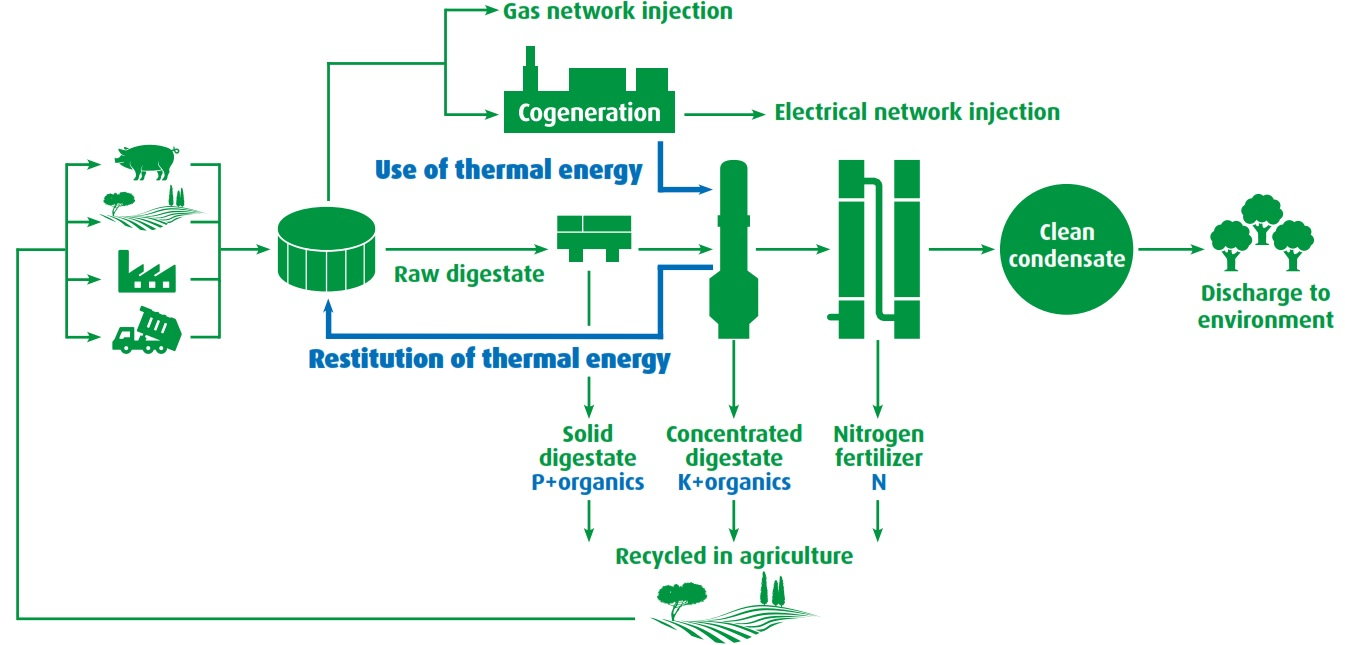

Anaerobic digester

Our technologies are also widely used in the area of anaerobic digestion, where they contribute to the enhancement of concentrated digestate as high agricultural value fertiliser: substantive amendment (organic matter and phosphate elements) and ammonium sulphate. Our technologies are used to separate N, P and K components to better target the spreading plans.

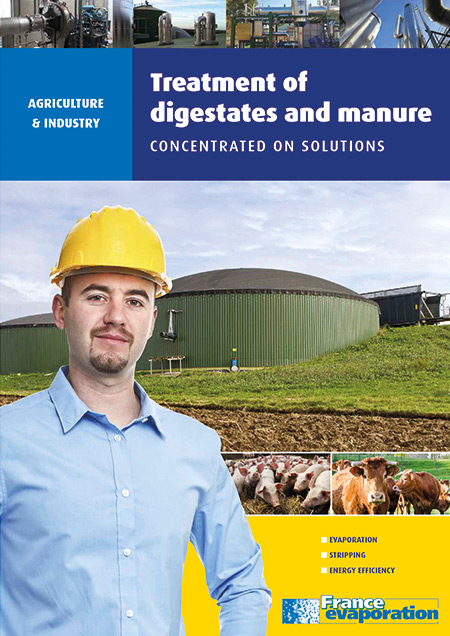

France Evaporation is a specialist in the treatment and recycling of digestates and manure. We are developing the most performing and most sustainable solutions for concentration and recycling on the market. Complete and user friendly, our solutions will reduce your operation costs.

A global solution for valorization of manure and digestates in an economical loop

An economical solution

An economical solution

- Reduction in the digestate volume

- Reduced costs for transport, storage and spreading

- Optimum re-use of products: fertilizer, amendments and biomethane

A regulatory solution

A regulatory solution

- Optimisation of spreading plans

- Purification for discharge into the natural environment

An eco-friendly solution

An eco-friendly solution

- Separation of the elements, N, P and K

- Development of targeted fertilizers, with high agricultural value

- Nitrogen fertilizers: ammonium sulphate/nitrate, ammonia water

- Organic-based amendments

A low-energy solution

A low-energy solution

- Optimisation of the plant’s yield

- High performance technology: Mechanical Vapour Re-compression (MVR)

A sustainable solution

A sustainable solution

- High level performance, steady over time

- Little sensitivity to variations in the input

- Very low breakdown rate

An ecological solution

An ecological solution

- Optimised energy consumption

- Maximum recycling of by-products

- Complete purification of discharged products

- 90% reduction in volume on average

- Service life greater than 25 years

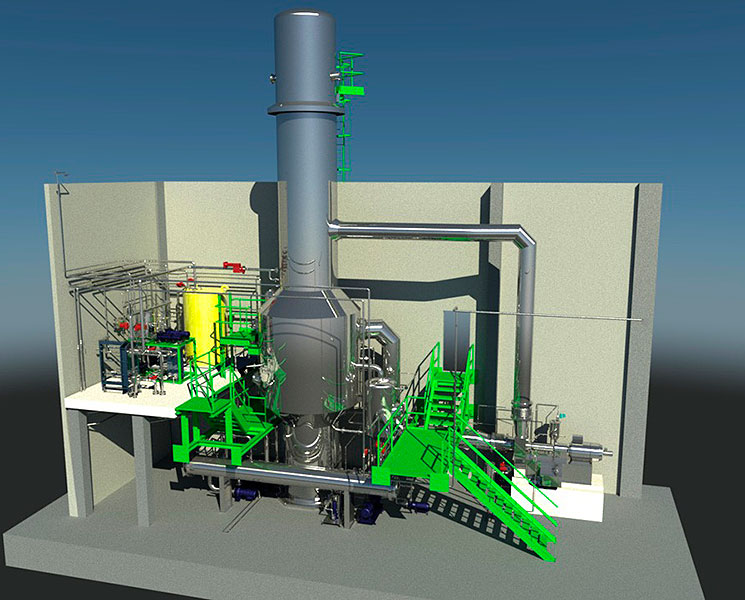

France Evaporation innovation

An innovative process for the recovery and recycling of energy, which boosts the overall performance of the plant.

- 100% of the biomethane recovered in injection

- Up to 50% reduction in overall energy consumption

Experience and expertise

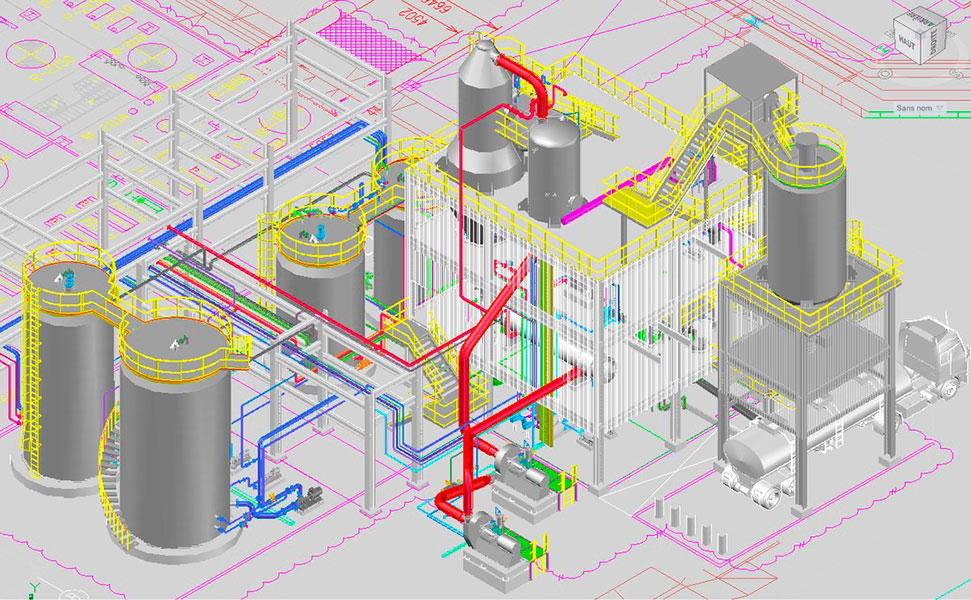

France Evaporation brings together a complete team of engineers specialised in the treatment of digestates and manure. It ensures you a global approach to your problems.

Experts in evaporation and concentration technologies

- Evaporation: falling film, forced circulation, under vacuum

- Stripping, reverse osmosis

- Energy efficiency, mechanical vapour re-compression, multiple effect

Complete and global intervention

- Installation survey

- Project development support

- Laboratory testing

- Pilot trial (in our workshop or on site)

- Turnkey projects

- Installation and start-up

- Maintenance and operation

25 years experience

- Unique expertise on the market

- Feedback which secures your projects

Great ease of use and maintenance

- 100% automated units

- Controlled maintenance

Compact units

- Incorporation into all types of sites

- Without environmental nuisance (noise, odours, etc.)

France Evaporation is a partner of BiogazVallée

Brochure

With over 20 years of experience, France Evaporation develops high performance solutions for the treatment and recycling of leachate.

Our teams design, test, manufacture and monitor complete, sustainable and efficient facilities, allowing for maximum reductions in the volume of leachate.

With a rapid investment return, our solutions mobilise the most energy efficient and innovative evaporation, concentration and distillation technologies for energy recovery from biogas.

The best evaporation and distillation technologies

Through advanced technologies mobilised by our teams (falling films, forced circulation), our facilities get maximum concentrations and can divide up to 100 times the volume of leachate treated: the concentrate obtained can be easily neutralised and stored.

The concentration performances of our facilities remain stable over time: little dirt and no flow reduction. Their lifespans are 4 to 5 times greater than those of membrane systems with a very low failure rate.

Good energy efficiency

Our facilities benefit from ongoing research on the improvement of energy efficiency: mechanical vapour compression, multi-pass circuit, etc.

They use thermal energy from biogas by cogeneration, enabling dual energy recovery. In addition: premium energy efficiency and a reduction in TGAP.

Full treatment of residues

Our stripping and oxidation technologies recover and neutralise ammonia nitrogen effluents.

The essential link of reverse osmosis plants

The inverse membrane and osmosis technologies suffer regular performance drops: clogging, low speed, rise in pressure, overloaded retentates, etc.

France Evaporation technologies complement these systems to quickly treat 100% of your effluents by significantly reducing your maintenance costs, with a concentration rate of 5 to 10 times higher.

By profound definition of our expertise in evaporation and crystallization, water treatment is a major specialty of our teams, developed for over 20 years: washing water tanks and the end of production (chemical products, cosmetics, pharmaceuticals etc.), ammonia solution, pig manure, laundry water and radioactive effluents.

Today, this specialty allows us to be at the forefront of the ZLD development process (Zero Liquid Discharge).

Our teams' experience covers all industrial sectors and a broad spectrum of effluents.

Objective: Zero Liquid Discharge

Recycling and water reuse are now priorities for industrial and environmental policies. In many industries, the goal is to achieve zero liquid discharge (ZLD).

France Evaporation designs facilities to meet regulatory thresholds and the strictest industrial objectives in this area, notably for sectors producing fossil or nuclear energy, effluents from refineries, chemical production processes, mining effluents and ISDND leachates.

Technical performance and energy savings

Our ZLD systems combine evaporation and crystallisation technologies as well as all stripping possibilities to separate the volatile components from the condensate to neutralise or reuse them.

For these complex systems, Mechanical Vapour Compression technologies developed by our teams are widely used to minimise energy consumption and operating costs.

France Evaporation develops complete thermal solutions for production processes in the mining and metallurgical industries.

France Evaporation's evaporation and crystallisation systems are integrated into the recycling and recovery of by-products and water treatment (ZLD / release into the environment).

Evaporation France has specialised skills and extensive experience in producing potash, salt, soda, nitrate and sulphate as well as in the treatment and recovery of ammonium sulphate, sodium sulphate, nickel sulphate and sodium aluminate.

Our crystallisation technologies can be applied to the production of certain special metals and allow the recovery of valuable by-products: vanadium, tungsten, molybdenum, lithium chloride.

IFC®: a revolutionary crystallisation technology for the mining industry

France Evaporation has developed a patented technology that has very interesting crystallisation performances for the mining industry:

- larger crystal size than that obtained by conventional technologies

- excellent distribution of crystals

- good energy efficiency

Being very innovative, this technology is already deployed in the Pentaborate and decaborate production units.

Our strengths

The multidisciplinary expertise and experience of our teams are major assets to rapidly develop the most suitable methods for your quality constraints, budget and industrial requirements.

The processes developed by France Evaporation combine evaporation, crystallisation and stripping to get maximum value from the products and by-products of the process.

Specialists in thermal energy, our teams have very advanced expertise in the optimisation of existing energy facilities including very large crystallisation and evaporation systems.

France Evaporation's study and working teams have comprehensive expertise in the food evaporation sector.

This experience enables France Evaporation to design and build concentration units combining energy efficiency, respect of product characteristics and ease of operation.

Applications

Our teams include specialists in the concentration of enzymes and molecules, by-products (vinasse, ammonium lactate, etc), animal feed products (alfalfa, vinasse, etc) and juice (fruit juice, cooking juice, etc).

Design and construction for the Agri-Food

Sheet metal equipment as needed to meet food sanitation standards (Ra, design, etc).

Energy optimisation

Through our experience, we have developed specific expertise in energy optimization of multiple effects units in energy recovery through the addition of vapour compressors on the syrup and bender concentration installations.

Our teams work with the most demanding players in the cosmetic and pharmaceutical industries. The solutions implemented notably affect the concentration of molecules, separation of solvents and concentration of washing water from the manufacturing tanks.