Mechanical Vapour Compression (MVC/MVR)

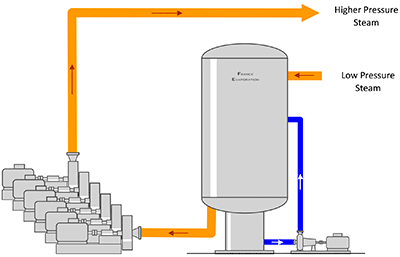

Mechanical compression raises the temperature and vapour pressure, allowing its reuse and a significant improvement in the energy performance of a facility.

Home > Technologies > Energy efficiency > Mechanical Vapour Compression (MVC/MVR)

Multiple applications

Mechanical Vapour Compression (MVC) has several applications:

- transformation of a single effect or multiple effect evaporator into Mechanical Vapour Compression

- vapour recovery for reuse in another workshop

MVC applications are multiple and are systematically the subject of specific studies conducted in collaboration with your team to define the most relevant patterns.

Investment return

With an investment return of 1 to 3 years, Mechanical Vapor Compression installed on your existing units will sustainably reduce your operating costs.

The changes proposed by France Evaporation do not impact the processes and capacity in any way.

High level technology

MVC/MVR is very reliable when properly sized and installed. We have been using this technology for over 20 years and maintenance costs are extremely low on the compressors we use.

To ensure this reliability, we use:

- A large separator, which allows for maximum separation of the evaporation vapour and avoids droplets forming in the MVC, in order to ensure the fan’s lifespan.

- Among our facilities, in addition to the separator, a vapour scrubber cleans the evaporation vapours and helps spread any remaining product droplets to preserve the blower mechanism. It also helps in countering foaming.

- on leaving the scrubber, a mist eliminator prevents any droplets

- Many additional securities to monitor and ensure the proper functioning of the installation: levels, temperatures, vibrations, etc.