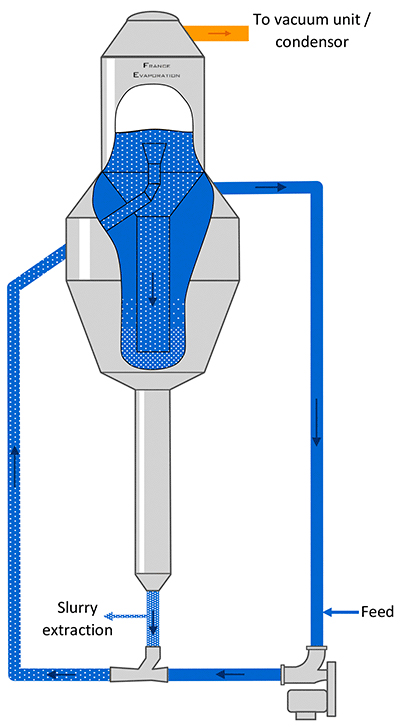

IFC® (Indirect Forced Circulation)

IFC® technology avoids contact between the crystals and the pumps or agitators built into the crystallizer, without reducing or altering their circulation. At stake: a very significant reduction in the rate of failure and very streamlined maintenance transactions.

Home > Technologies > Crystallization > IFC® (Indirect Forced Circulation)

Safer and more sustainable

IFC® specifically meets the needs of markets:

- average size of larger crystals

- better distribution of size

Crystals with larger sizes for maximum upgrading

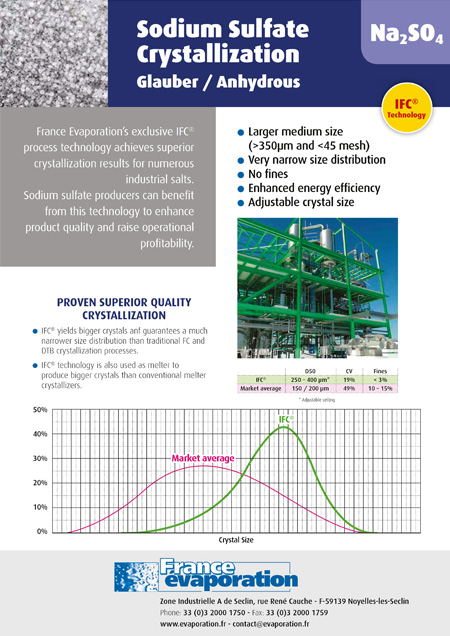

IFC® ensures an average crystal size (D50) greater than that obtained by a crystallizer.

A high quality production through an excellent distribution of crystal size

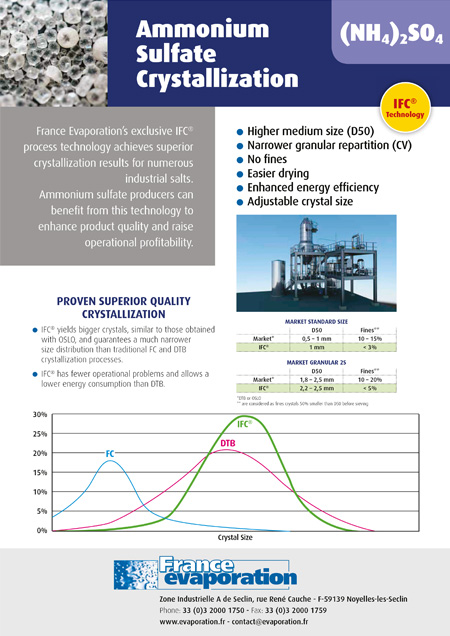

The size distribution of the crystals obtained by crystallizing IFC® is close to the average size, the amount of fine is greatly reduced compared to other crystallization technologies.

The IFC® design allows a better control of secondary germination.

As such, the IFC® crystallizers guarantee a very high quality production, regular and simpler to develop in markets including the most demanding (pharmaceuticals, Chemicals, etc.).

A production of very reduced fine

IFC® produces less fines than other technologies on the market, so the proportion of fines at the end of the drying process is reduced. Typically it is less than 3% compared with 10% for other technologies.

Energy efficiency

The IFC® technology provides crystal sizes equivalent or even higher to those produced by DTB crystallizer, but with a much lower energy consumption, in the case of a MVC / RMV unit.

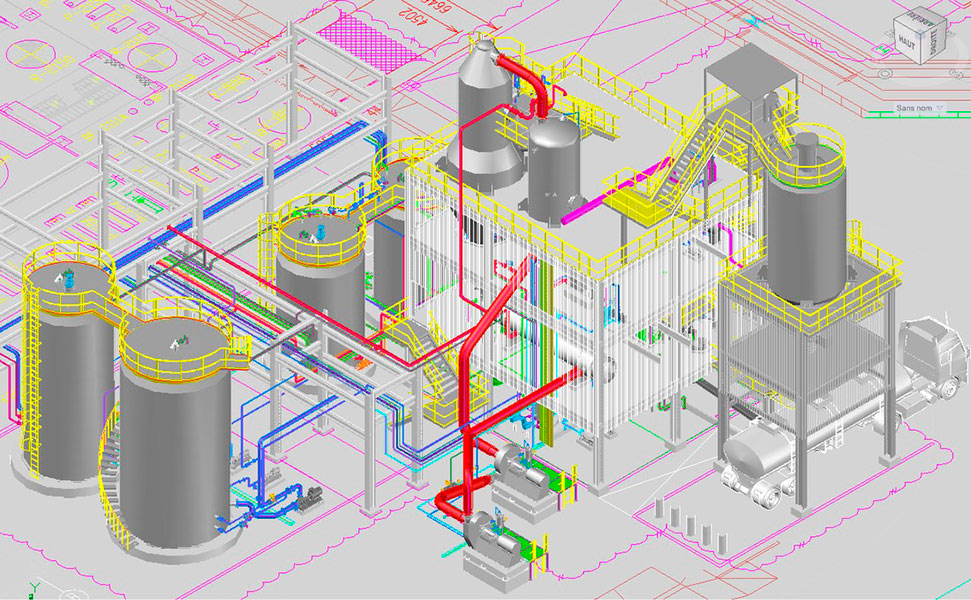

IFC® in action

Several IFC® crystallizers were designed and launched in 2011.

- For the production of Na2SO4, installation performances reach a d50 greater than 400μm (against a d50 of 250µm on other technologies).

- For the production of (NH4) 2SO4, the IFC® technology allows to obtain crystals with a d50 greater than 2 mm and a crystal distribution of 25%.