Chemical

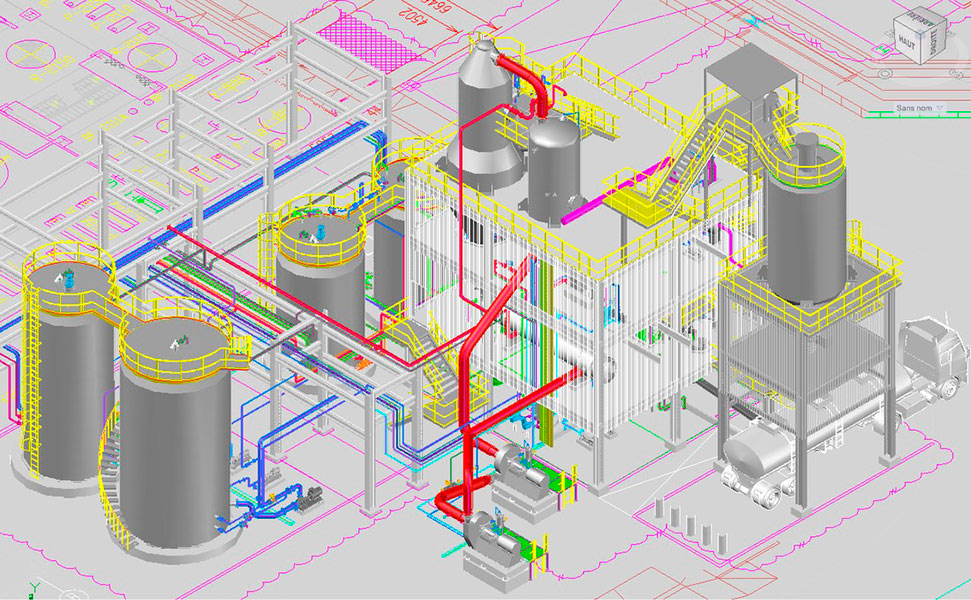

Our facilities can handle everything from simple optimization requests to the design of complete processes for the production of high value-added compounds.

Home > Industries > Chemical

Our strengths

FE by France Evaporation est un acteur clé dans la production de matières à forte valeur ajoutée, notamment dans le secteur de la chimie. Nous intervenons à chaque étape : purification, extraction, isolation ou création de composés. Notre savoir-faire et nos technologies soutiennent des projets à l’échelle mondiale. Nos compétences ne se limitent pas à nos propres équipements : nous savons intégrer les outils et partenaires nécessaires pour réaliser une ligne de production complète.